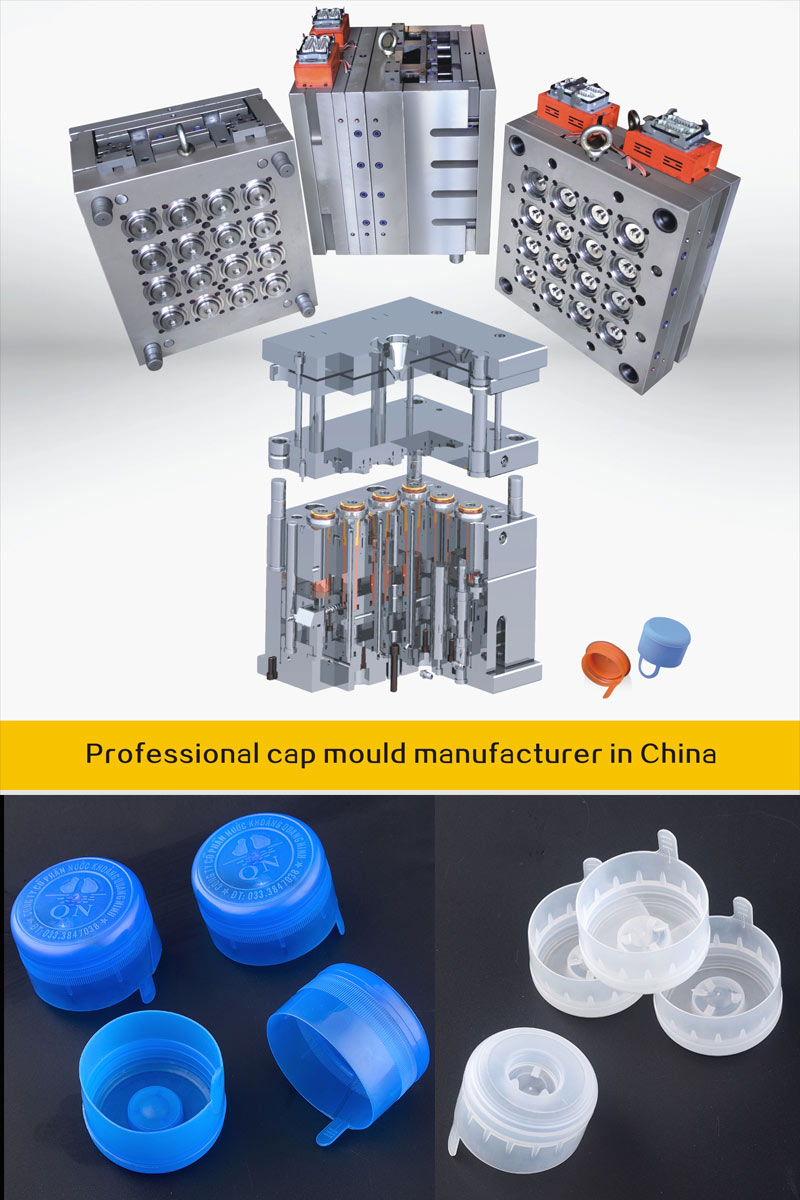

5 gallon bottle cap die is popular in market as its high production ability and high quick benefit return. To follow time development, we aimed to provide 4-64 multi-cavities and 5 gallon bottle cap molds technology becomes mature.

What definite a good 5 gallon cap mould?

1.Design. Our cap design team had engineers which at least 8 years in 5 gallon cap molding. They knew suitable thickness, good tear system design for not easy broke and balance injection. Besides, mold designer provided simple structure which also had optimal coolingand air venting system.

2.Working experience. Each month,we exported 20-30 sets 5 gallon cap dies to all over the world. Mold makers are serious and rich experience.

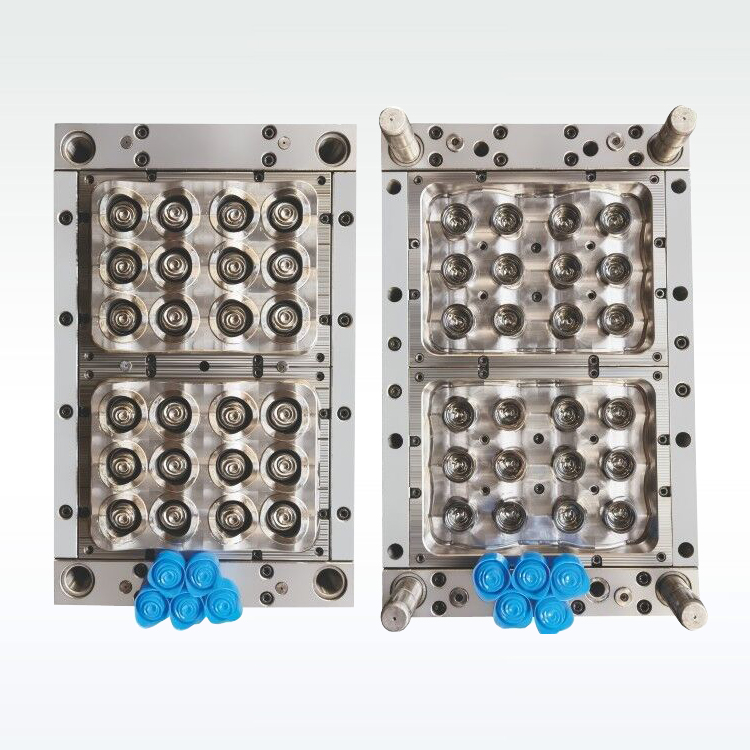

3.Tooling equipment. We use S136 steel for cap mold core and cavity, and P20 steel for mold base. This could guarantee 1 Million-3 Million shots mold life. Besides, two times tooling, rough and precision tooling which ensure precision 5 gallon cap mould size.

4.Quality control service. QC willcheck after each step tooling. Once got green light, it could continue making.Besides, QC will check it’s smoothly running at least 8 hours.

| 5 gallon bottle cap mould |

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

| 2.Quotation Making | Mould Quotation will be finished in 1 day according to information we get. |

| 3.Negotiation | The quality, price, material, delivery time, payment item, etc. |

| 4.Mould Design | 1-2days for product 3D/2D drawing design as per customer's design or our company's design. Then in further make the mould 2D/3D design. |

| 5.Mould | 1. confirm the proucts and the mold design |

| 2. Mould material prepare |

| 3. Rough machining(heat treatment on mold base and pre-harden on mold) |

| 4. CNC/ Vacuum Hardening on mold main spare parts |

| 5. finishing machining( JDPAINT, DEM.etc) |

| 6. Dimension inspection |

| 7. Ejector& runner& cooling & other device process |

| 8. Assemble mold |

| 6.Mould Testing | When moulds are finished, we will test the mould and we will send samples for consumer reference. |

| 7. Sample confirmation | If the first sample is not satisfied by customer when it is come out. We modify the mould and until meet customer’s satisfaction. |

| 8.Delivery | Delivery goods by sea or by air, according to customer’s requirement. |